STAGE | Construction

TECHNOLOGIES | Artificial Intelligence (AI), Cameras, Sensors

SUMMARY

Artificial Intelligence (AI) based Health and Safety Monitoring solutions rely on the use of AI and technologies to monitoring construction sites. With AI programs, using data collected from the sensors such as movement detection, CCTV, heat sensors, weather sensors, it is possible to identify social distancing, hazards, safety protection equipment utilisation, personnel proximity to hazards, intrusion detection, etc. and trigger an alert before safety or health incidents occur, as well as after they have occurred, if they could not be prevented.

Using AI and computer vision, movements and interactions of workers, machinery, and objects on a construction site can be assessed and tracked in real-time, against predetermined Key Performance Indicators. Such solutions, support site and safety managers in being able to better monitor and have better visibility of the work site, so they can better control the interactions and ensure health and safety for the workers.

Working in construction is dangerous and it is estimated that US construction workers are killed on the job five times more often than any other workers. The main causes of construction deaths in the US are falls (33.5%), struck-by objects (11.1%), electrocutions (8.5%) and caught-in-between accidents (5.5%). The struck-by death toll has risen by 34% over the past decade. Additionally, the non-fatal injury rates in the US construction industry are 71% higher than any other industry, making safety a priority for each construction firm. Site and safety managers and workers need to find ways to minimise workplace injuries and reach a zero-death goal. Additionally, as demonstrated by pandemics like COVID-19, site managers need to control worker health onsite to prevent any disease outbreak or to identify the sources of those outbreaks if they occur.

AI systems used in conjunction with the relevant sensors (collecting data on health and safety) help to reduce workplace hazards. AI can detect if the construction site workers are correctly wearing the required safety gear and alert them if they are missing any equipment. The technology can also monitor vehicles or personnel, allowing only authorized parties to enter the areas without manual intervention, which can prevent intrusions on sites.

Using the latest sensors technology, real-time information can be captured on:

- High risk areas: Exposure to hazards is a risk that affects workplace safety (e.g. working from heights, exposed electricity wires, chemicals, toxins, heat, machinery, etc.). For example, site sensors (taking temperature measurements, moisture levels, and other indicators) enable the identification of toxins in the air or in building materials and the safety of the surrounding environment. The use of wearables for workers is also valuable in hazardous settings, as it is possible to detect red flags such as heat, gas or lack of movement. In this way, safety measures can be established to limit the exposure of workers to hazards.

- Onsite workers with potential health issues or high-risk interactions: Using mobile devices, real-time site information can be made accessible to all, and site managers as well as workers can detect conflicting movements and activities as they happen and work more productively. If one of these red flags occurs, nearby co-workers, management, or even emergency services, can be automatically alerted.

- Intrusion risks and threats.

There have been several implementations of AI in construction work, however, those practices need to be expanded and implemented by more contractors. The COVID-19 outbreak has hastened the development of these solutions, such as the use of automated risk assessment applications for workers at the entrance of work sites that can check workers for symptoms and epidemiological factors.

In the future, sensors combined with AI are likely to be implemented in work procedures to improve safety at construction sites, such as incorporating wireless devices to connect machines and personnel to a central operating system.

VALUE CREATED

Improving efficiency and reducing costs:

- Increase visibility of worksite activities for the site and safety managers to avoid safety incidents, thus reducing disruptions and costs associated with delays.

- Reduce costs associated with worker compensation and litigation by reducing and better tracking incidents.

- Enhance site works by optimising the number of workers and activities performed by workers on site.

Enhancing economic, social and environmental value:

- Improve safety at construction sites by identifying hazards and alerting health and safety regulators when things go wrong.

- Enable construction works to continue during disease outbreaks such as COVID-19.

- Enhance construction site workers’ experience by improving work safety.

POLICY TOOLS AND LEVER

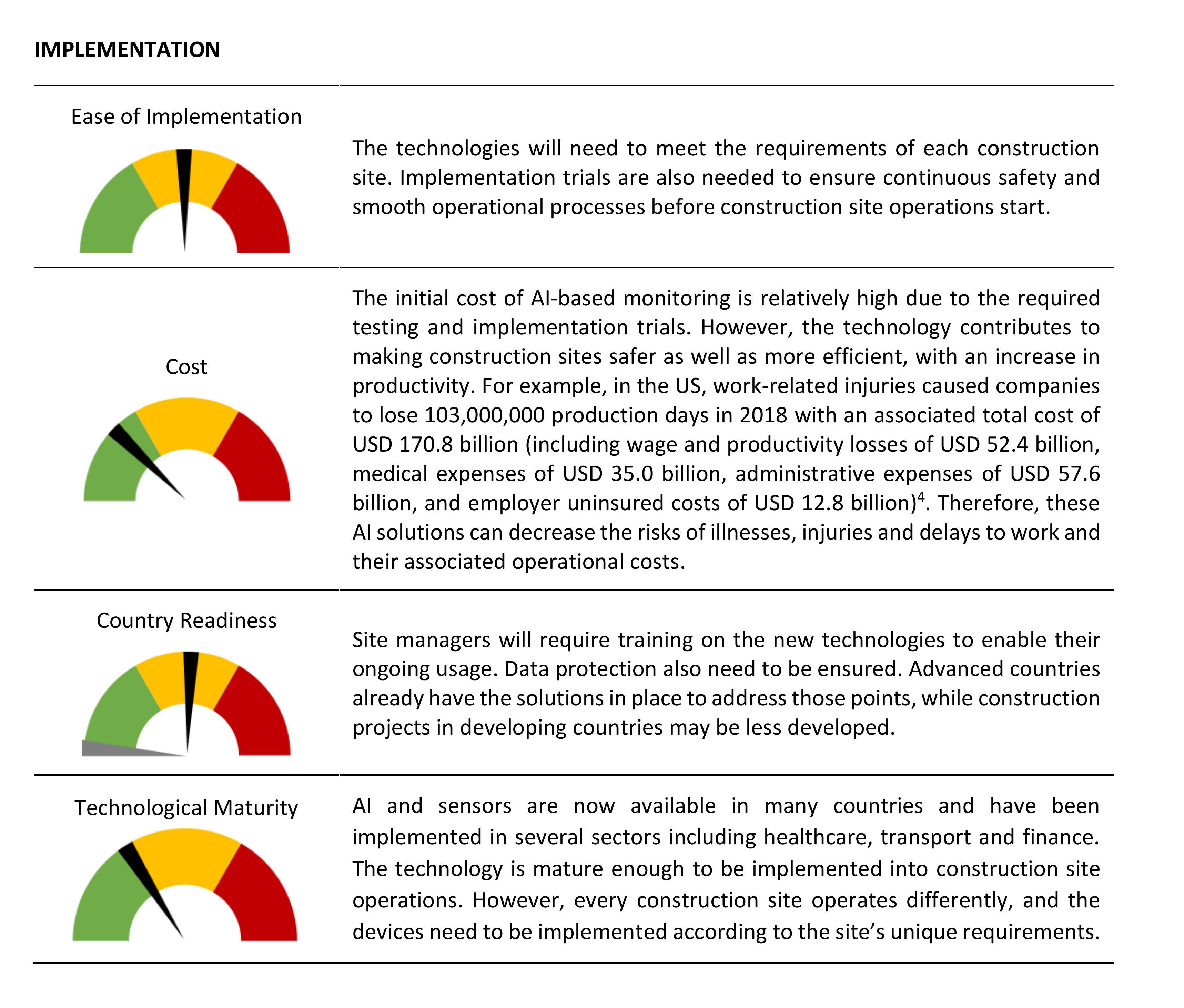

Legislation and regulation: Governments are developing standards for the use of these AI-based devices. The devices need to be tested and the data needs to be analysed in order to determine its suitability to be used in construction operations. Implementation trials must be performed to ensure the reliability of these systems.

Transition of workforce capabilities: Site and safety managers and technicians should be involved in the installation of the sensors at construction sites and trained in the use of AI-solutions. Working processes on construction sites will be changed with the integration of the AI technology. Construction site workers and managers need to understand the working process to use and maintain the AI-based devices.

Procurement and contract management: Government procuring agencies can play a key role in accelerating the use of such technologies by requiring contractors to use such technologies and choosing contractors with a proven track record.

RISKS AND MITIGATIONS

Implementation risk

Risk: Every construction site operates differently. Therefore, one device might not work well with all construction sites. Moreover, there may be a lack of understanding of the technology, which can lead to accidents and delays during operations.

Mitigation: Site Managers must ensure the right requirements and Key Performance Indicators are in place for the devices to enable them to be tailored for each construction site. Additionally, site and safety managers and workers need to be informed and trained to understand how to interact, use and maintain the AI-based devices.

Social risk

Risk: The implementation of the technology could be perceived as a risk for workers who may worry that the technology could result in their redundancy (e.g. on-site safety staff). Furthermore, site workers in general may feel the technology is intrusive as it watches and analyses their movements and activities.

Mitigation: A change management plan should be developed that highlights the changes to existing job roles and responsibilities for all staff affected by the technology. Trainings should be undertaken in response to these changes in job responsibilities. Communications with staff should be used to address their concerns regarding privacy. These communications should highlight the safety benefits of the technology, which will benefit them directly, and the security of the data collected.

Safety and (Cyber)security risk

Risk: AI-based monitoring generates real-time data about workers, their movements and activities. It may also collect data related to their health. Therefore, the is a data privacy risk that the data collected could be hacked due to cybercrime.

Mitigation: Companies should ensure their systems are robust to eliminate the risk of cybersecurity. Furthermore, governments should set legislative frameworks to outline the requirements of these systems to repel cybersecurity attacks and protect data.

EXAMPLES

Example: Suffolk

Implementation: The company is developing an algorithm that analyses photos from its job sites and scans them for safety hazards.

Cost: Suffolk’s productivity is estimated to increase by 14 to 20 percent in a few years.

Timeframe: Suffolk’s algorithm is based on various information including 10 years of scheduling data.

Example: The Learning Camera, UK

Implementation: The UK government’s innovation agency, Innovate UK, is conducting trials where footage at work site entrances and exits are monitored by cameras connected to a real-time video analysis platform powered by machine learning algorithms.

Cost: Innovate UK is providing GBP 200,000 of funding for this initiative.

Timeframe: The initiative took place between February 2019 and October 2019.

Example: Pillar Technologies

Implementation: Pillar has developed devices that include eight different sensors to monitor temperature, humidity, particulates, air pressure, ambient light, noise, VOC’s and carbon monoxide at construction sites and alert users when issues are identified.

Timeframe: They now plan to aggregate data collected by the devices to run predictive analysis algorithms.

CONTACT INFORMATION

Devina Hassanaly

Systra

Director, Mobility and Future Cities