SUMMARY

Novel welding processes and automated welding technologies are used in the pre-fabrication and construction phase of infrastructure projects. These technologies increase productivity and decrease production time by automating repetitive welding tasks, improving welding quality and consistency, and augmenting the skills of welders. New business models such as ‘Weld-as-a-Service’ are assisting in mitigating the high capital cost associated with automated welding technologies. Though this technology can be used in many infrastructure sectors, this use case explores its use in water related infrastructure such as pipes, tanks and treatment plants.

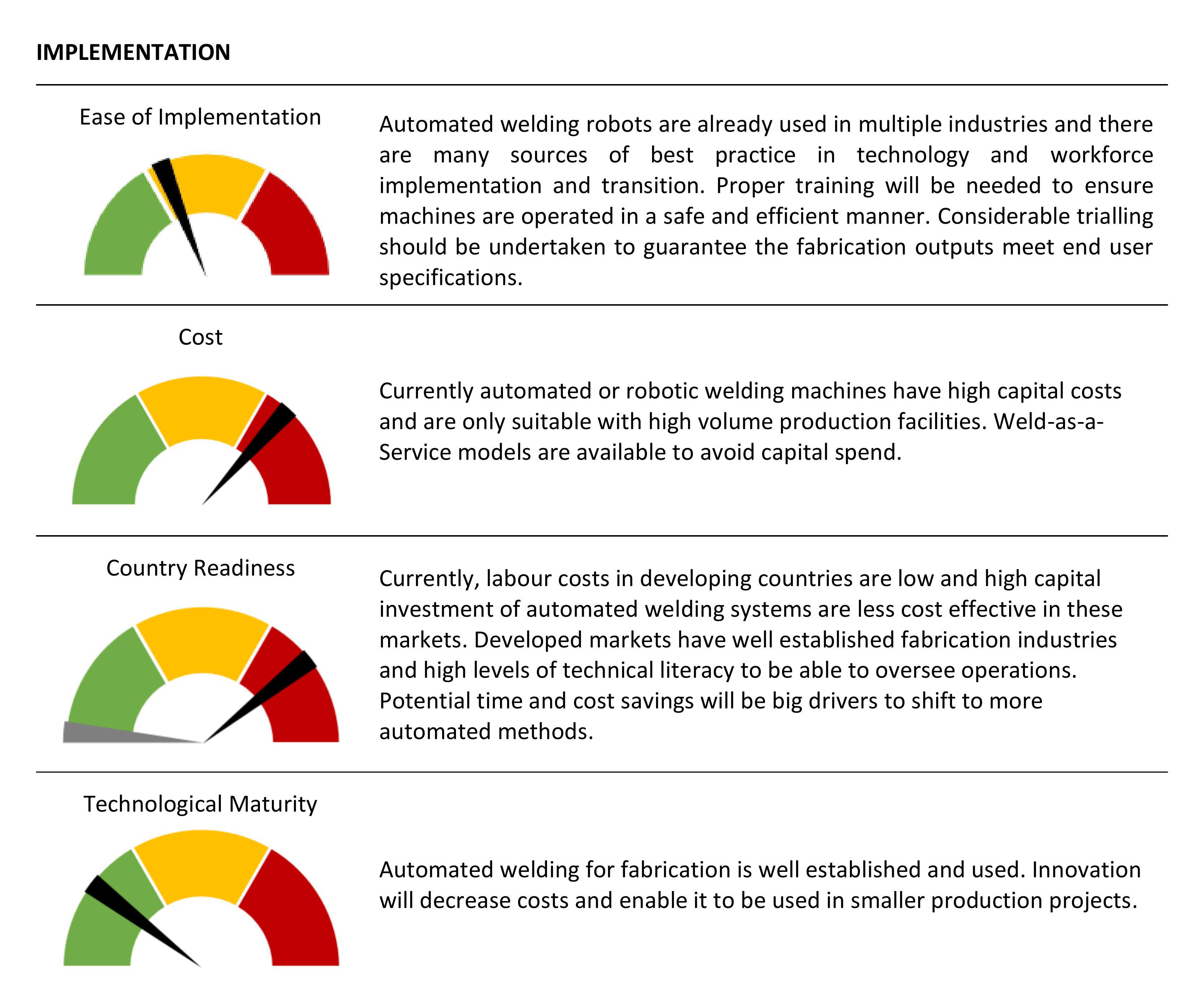

Typically, automated welding technologies are only used for sophisticated high throughput production facilities due to the high capital requirement. As costs for automation decrease and welding technology becomes more advanced, there are new opportunities to use automated welding in small and medium sized fabricators and production runs. Welding robots may be pre-programmed, guided by machine learning technology, or by a combination of the two methods.

In 2020, it is forecast that USD $70 billion will be spent on new pipes and USD $118 billion on construction and fabrication of water and wastewater infrastructure globally[1]. There is a large opportunity to reduce infrastructure costs through pre-fabrication from automated welding. Welding and fabrication are labour intensive industries in both developed and developing markets. Reliance on manual human welders can dramatically increase a fabricator’s labour costs. This can have a negative impact on production costs for infrastructure projects. As with many skilled trades, there is a shortage of skilled and experienced welding operators in many markets. Automation can therefore fill the labour gap.

Automation saves time and costs on repetitive welds, increasing production efficiency. Robotic welding devices provide increased accuracy, repeatability, and throughput for fabricators with high volume applications enabling welders to concentrate on more complicated tasks. Lower costs can also assist to keep local and smaller small and medium enterprise fabricators competitive with larger fabrication companies.

Innovation with more complicated welds can enable prefabrication of more types of parts and further increase cost and labour savings. As the technology develops, the cost of automated welding will decrease even further which will continue to make it more accessible.

VALUE CREATED

Improving efficiency and reducing costs:

- Decreased labour costs and time of production while increasing output

- Increased quality of final product through increased quality, accuracy and consistency on repetitive and critical welds

- Improved welding efficiency results in less scrap metal and consumable gas and filler metal usage

Enhancing economic, social and environmental value:

- Assist onshore fabrication industries to be competitive with offshore fabricators

- Assist Small and Medium Enterprises (SMEs) to stay cost competitive with larger companies

- Decrease safety risks for workforce

POLICY TOOLS AND LEVERS

Legislation and regulation: Legislation to incentivise onshore fabrication of infrastructure can be considered to keep industries from going to offshore manufacturers. Ensure relevant design and construction standards are updated to reflect use of automated welding.

Transition of workforce capabilities: With automation being able to complete simple and repetitive welding tasks with high quality and consistency, skills will need to shift to operating, maintaining and overseeing automated systems and focus on more complex value-add welding products. Trade schools and training organisations will need to adjust their courses and offer more automation-centric education.

Procurement and contract management: Contracts should include flexibility to allow for use of automated welding alongside traditional manual welding. This might include both the requirements of the welding activity and the inspection program.

Funding and financing: Assisting local and small and medium sized enterprises in funding for new technologies can help to create a level playing field.

RISKS AND MITIGATIONS

Implementation risk

Risk: There are different levels of automation that companies can achieve. Issues can arise when trying to shift to a high level of automation too quickly. Transition projects that do not have realistic scopes or initially automate too many processes will find that projects that cost too much, take too long to implement, and fail to deliver cost and efficiency targets.

Mitigation: Successful automation strategies must align with business and operations strategies. Companies must have clear and deep understanding of fabrication processes and costs to choose the right level of complexity to meet their needs and have a solid return on investment.

Social risk

Risk: Automation can create the need for re-training of workers to operate, maintain and oversee automated systems and focus on more complex value-add welding products.

Mitigation: Government and industry can assist through training and up-skilling programs to help mitigate these issues.

Safety risk

Risk: Safety risks such as increased crush risks and electrical or mechanical faults causing machine malfunction can put operators at risk.

Mitigation: These risks can be managed through the implementation of safety precautions including physical barriers and sensors to keep workers at a safe distance and automatically shut it down when people are too close.

EXAMPLES

Example: K-TIG

Implementation: The Acueducto Gran San Juan project in Argentina consists of the installation of a new drinking water system to transport water from wells located approximately 25km west of the city of San Juan to complement the existing water system. 15km of this pipe was fabricated from stainless steel and welded using the automated K-TIG technology.

Cost: The project is being jointly funded by the Kuwait Fund

Timeframe: The use of K-TIG transformed the economics of the project and the fabircation was completed in 162 days. The orginal timeline was 720 days with traditional welding methods.